Businesses

1. Circular Bored Pile

Circular Bored Piles are usually used as the foundation of large-scale structures especially those located in a limited area where driven piles are not applicable due to transportation and ground vibration problems. Moreover, compared to driven piles, bored piling technique causes no lateral movement of soil underneath that may affect nearby structures, less noise pollution and less ground vibration. The Company offers various sizes of pile ranging from 50 centimeters to 200 centimeters in diameter and deeper than 80 meters depending on the design load and local soil properties.

2. Ground Improvement by Jet Grouting

The objective of ground improvement is to strengthen the existing soil structure which can lead to the increase of soil bearing capacity and prevention of lateral soil movement. The Company provides this type of service by injecting cement grout at a high pressure between 200 to 400 bars. Type of work can be categorized as follows:

2.1 Soil Cement Column

This type of ground improvement is used to strengthen the soft soil properties throughout its whole layers. The process starts from jetting water downward at high pressure to stir the surrounding soil into the designated shape and size. Once reaching the level of pile tip, cement slurry is injected to mix with surrounding soil to create the solidified soil cement column that has ability to carry a vertical design load and reduce the settlement of structure above. The soil cement column produced by Jet Grouting has better properties and more homogeneous texture than those produced by other techniques such as low pressure mixing and rotary dry mixing. At present, soil cement column has been applied to various types of works such as road foundations, airport runways, dams, water gates as well as slope protection of canals or river banks.

2.2 Localized soil improvement

This type of work is used to improve strength and properties of soil or rock in a specific area; for example, grouting cracks in rock or soil for dam construction, grouting to improve stability of soil for excavation or drilling purpose in a specific area.

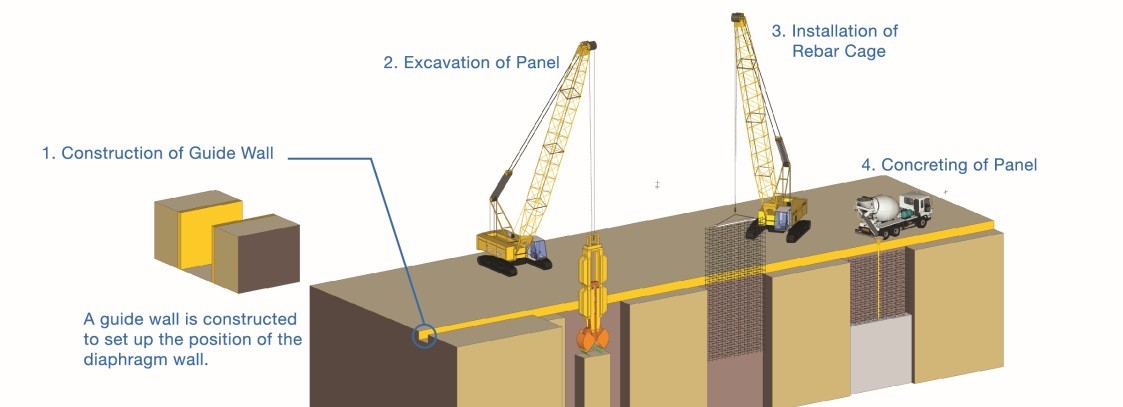

3. Diaphragm Wall/ Barrette Pile

Diaphragm wall is an underground reinforced concrete wall constructed to be a load bearing and retaining structure to prevent lateral soil movement. Construction process of diaphragm wall is similar to that of wet-process bored pile. Diaphragm wall can be used not only instead of sheet pile but also as a permanent underground wall with water-resistant and load bearing capacity. Diaphragm wall is generally used as the structure of underground car park, subway station, underpass, etc.

In designing a retaining wall, its thickness can be determined from 50 cm to 1.5 m. The construction process starts with excavating the ground according to the size and the alignment of the wall to be built. Then, a borehole stabilizing slurry (bentonite and polymer) is filled to protect the excavated trench against soil collapse. After that, a steel cage is installed and a concrete is poured into the trench. After the concrete has set and reached the required strength, the underground excavation will be performed as well as the construction of underground structures.

A barrette pile is a cast-in-place reinforced concrete pile with a rectangular shape. It is a popular alternative when requiring a high bearing capacity of more than 2,000 tons per pile or for a limited construction area where a circular bored pile is not suitable. Its cross section size can be adjustable with a width ranging from 60 cm to 1.5 m, a length ranging from 2.5 m to 3.0 m, and a depth of more than 60 m. depending on the designed load bearing capacity and the soil layer composition of the construction area.

A barrette pile is constructed by excavating the soil in accordance with the required cross section size and depth. A stabilizing slurry (bentonite and polymer) is added to protect the borehole against soil collapse. After excavation, a steel cage is installed and a concrete is poured.